We, BOTTMAC India Pvt. Ltd., are India’s no. 1 Liquor Bottling solution provider. A pioneer in offering complete turnkey Liquor Bottling projects to our clients and an ISO 9001: 2015 certified company, we have been Manufacturing, Supplying and Exporting a complete range of Liquor Bottling Plant machinery and equipment since our inception in 2000.

A trusted name in the Liquor Bottling industry, Director of BOTTMAC India Mr. Kavinder Singh is a professional turned successful entrepreneur. Mr. Singh who became an entrepreneur at a very young age has now more than 20 years of experience in the business. He is committed to total client satisfaction and identifies their specific needs, translates them into quality products and provides them dependable services with utmost ease and a smile on the face. This has led him to develop new and innovative technologies for the betterment and advancement of the industry. He is the real driving force behind the company’s spirit, its commitment to superior quality, and growth and success of BOTTMAC India.

The company is headquartered in Ghaziabad, a Delhi-NCR area well-connected to the national capital and has continually grown its stature since 2000.

Vision : Become an industry leader with growing responsibilities and passion to lead the world.

Mission : Be the first and the only choice for liquor bottling plant manufacturing, of clients and be employee-friendly.

We are your one-stop solution provider for all your liquor bottling solutions. Our offerings are delivered on time and with guaranteed performance. They include the following:

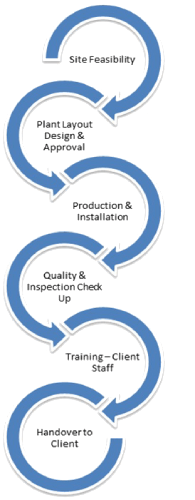

At BOTTMAC India, we implement the below best practices to reduce administrative burden and streamline management

Our name is synonymous with superlative quality, reliability and durability. We strive to maintain consistency in our product quality. An in-house quality control unit and a team of expert procurement agents, production supervisors and quality controllers assist us in meeting the highest standards. Adhering to the industry guidelines, we develop the machines in our production unit through latest production technology. Once the production stages are completed, our quality controllers take charge and closely inspect design and performance of each machine. The ready products are sent to the packaging unit, from where the organized consignments are dispatched for final delivery through various transportation mediums. We run an extensive quality check at every step of the project cycle, starting from testing the quality of the raw material in the beginning to testing done at the time of delivery to the client. We have 3 levels of quality checks in place:

We are the foremost and most preferred choice of PREMIUM brands in India – RADICO, DIAGEO, ALLIED BLENDERS & DISTILLER (ABD) and PERNOD RICARD INDIA, to name a few for all bottling manufacturing industry solutions. And with 150+ turnkey projects to our credit we have achieved the following: